Digital Manufacturing

- Business Area

- Digital Manufacturing

Leading digital manufacturer spearheading the convergence in the manufacturing industry.

Companies around the world are focusing on creating new values by integrating digital technologies to traditional industries. The industries are embracing innovation as the paradigm shift is happening in the manufacturing sector with the integration of digital space and off-line space.

Digital manufacturing can create values by reducing future risks, increase intangible asset and offer numerous practical benefits by reusing knowledge.

We offer innovative and practical solutions that help companies in desperate need of a breakthrough or improvement.

DOWNLOAD

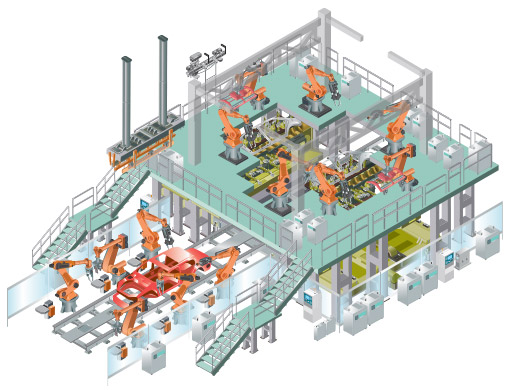

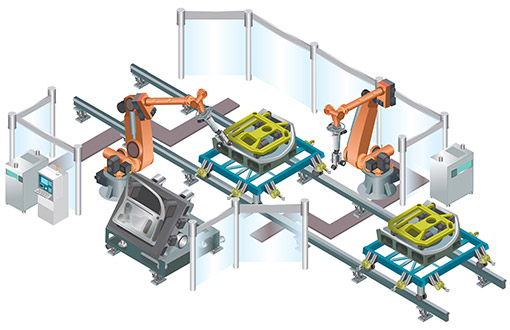

- Verification of interference between equipment and robots

- Optimization of layout

- Efficient distribution of welding points

- Analysis of cycle time

- Process design considering the order of robot motions and work environment

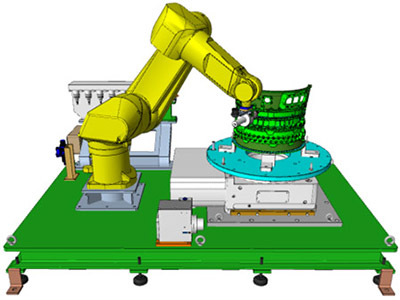

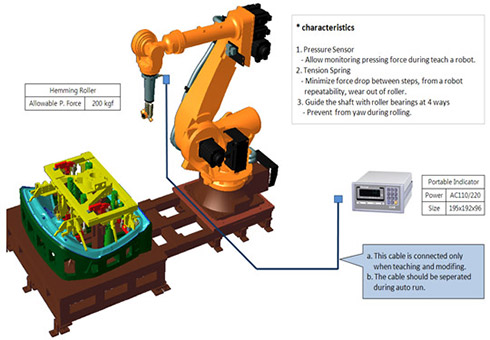

Roller Hemming System

- Business Area

- Roller Hemming System

The technology is used for hemming the edges of door, hood, and panel of chassis. Instead of using hemming press that uses the oil cylinder or electric motor, the hemming tool is attached to the upper part of the robot and fold the hemming flange for two to three times.

The hemming by using the hemming tool attached to the end of the robot enables the reductions in work space and production cost in comparison of the traditional press work.

DOWNLOAD

The system has a library equipped with different kinds of rollers to promptly respond to the needs of our customers.

The hemming rollers can be attached to the four sides.

Individual roller assembly offers flexibility for change of rollers or maintenance service.

CAD/CAM with Robot

- Business Area

- CAD/CAM with Robot

Moving beyond the conventional CAD/CAM methods, we are creating a new market with flexible robotics solution in this ever-changing industry. We are producing low-cost high quality products by increasing production capacity and flexibility by replacing CNC milling machines and others based on industrial robot technology. This provides enhanced speed and flexibility to our customers facing challenges in this highly competitive market. DOWNLOAD

The industrial robots are increasingly used in production facilities to carry out deburring, trimming, polishing and welding and component installation and machining, and water-jet cutting. But the use of these robots are still limited due to the lack of engineering and solution.

Robotmaster will be a perfect solution to these problems.